We Raloyal focus on converting machine making since 2009. Customizing solution to help clients to improve efficiency and optimize their supply chain.

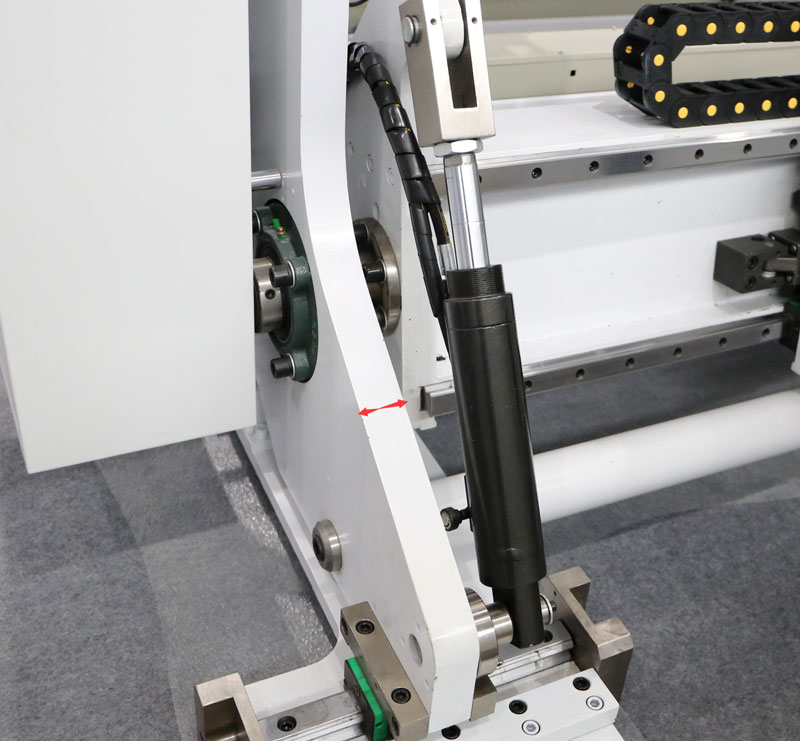

1. Machine bodies with steel materials, body heavy, smooth operation, to ensure that large materials in the high-speed machine stability. Strong and durable, to extend the life of the machine to ensure a longer service.

2: Semi-automatic/fully automatic blade set

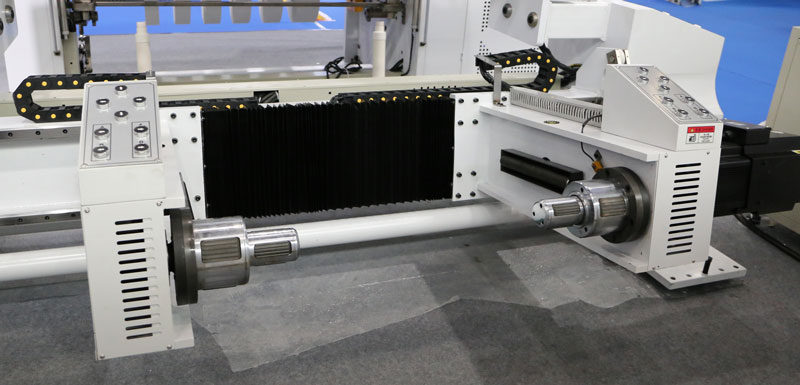

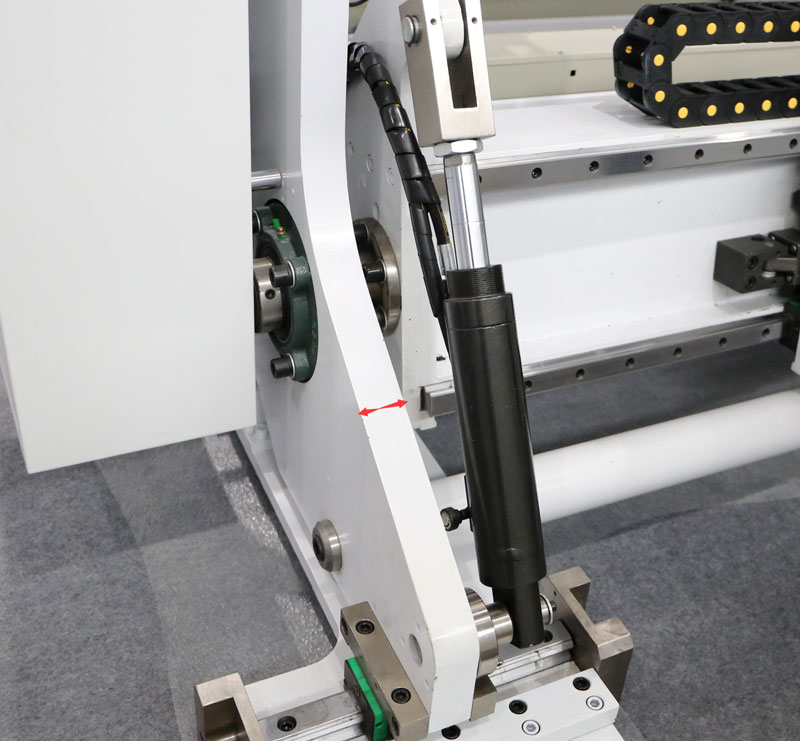

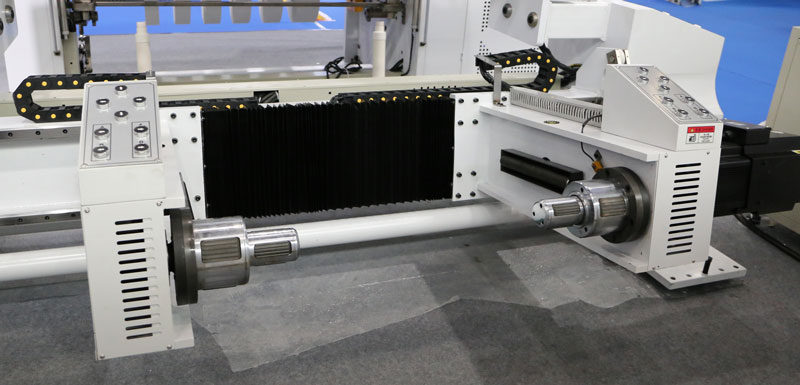

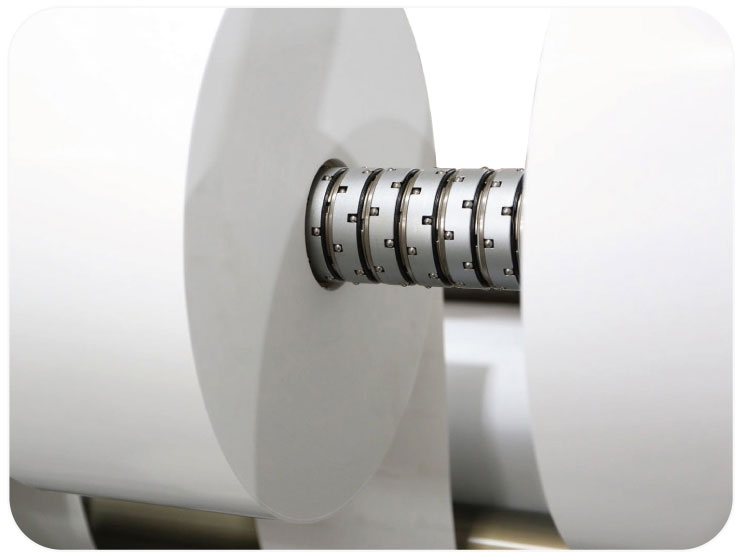

3: Shaftless loading, 2 mechanical chuck can moving left and right both alone and together, the real realization of no human participation in the material loading.

4: Automatic pusher to improve the productivity

5: Automatic Unloading for more friendly operation

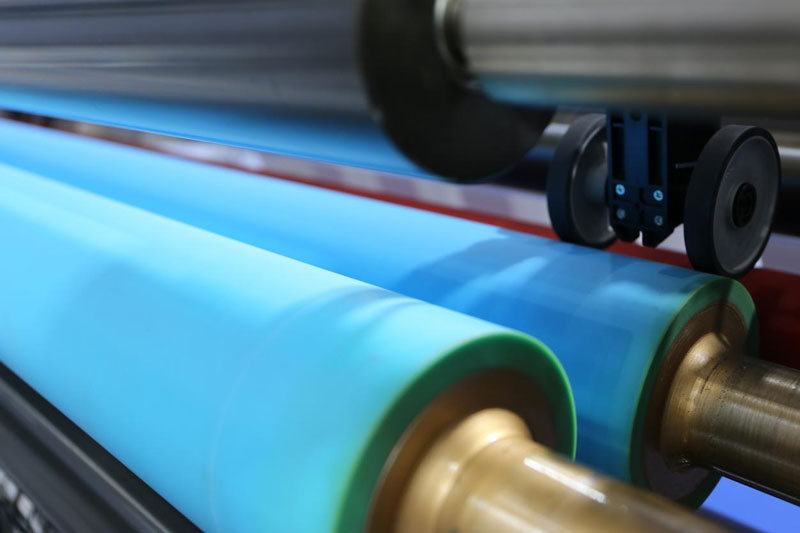

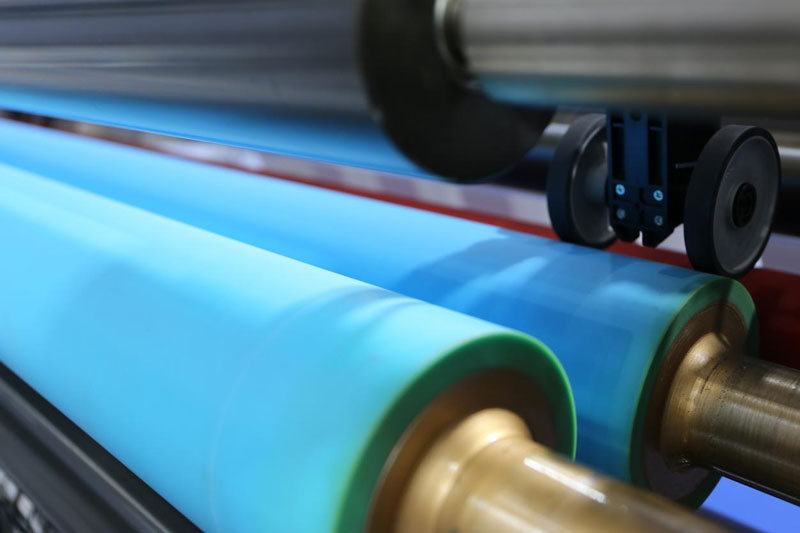

6: Double S traction is the ideal design for self-adhesive material, which can avoid the glue leaking and keeping the material surface clean.

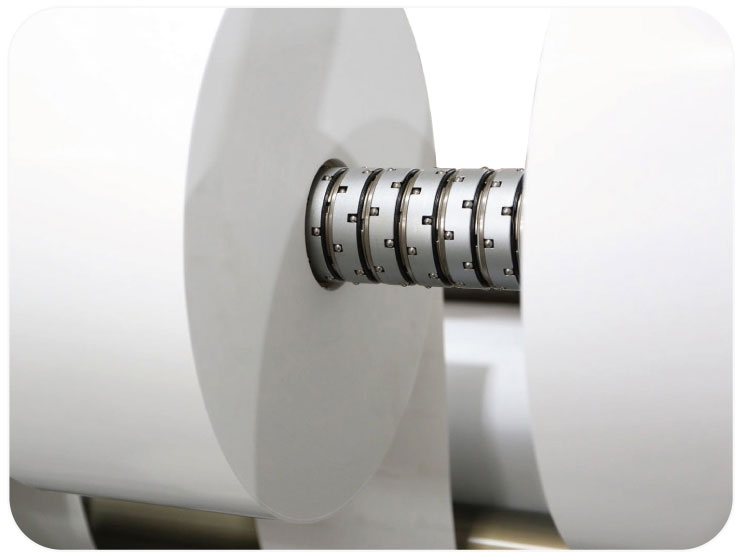

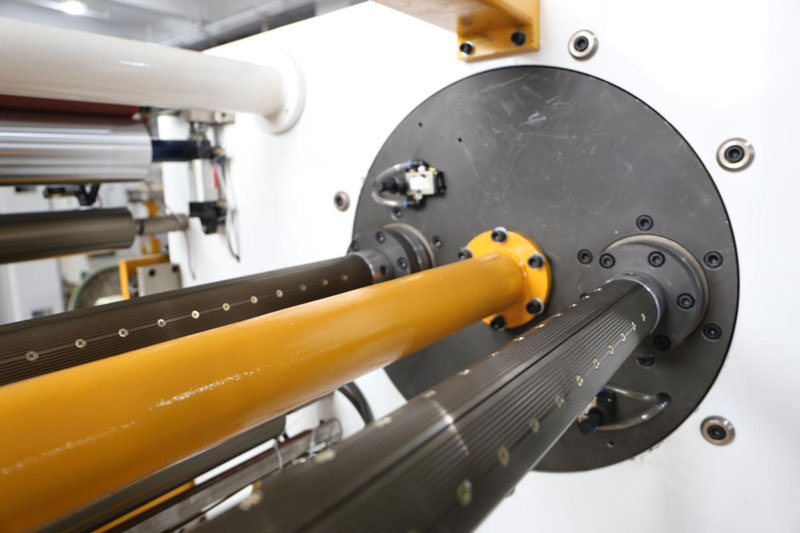

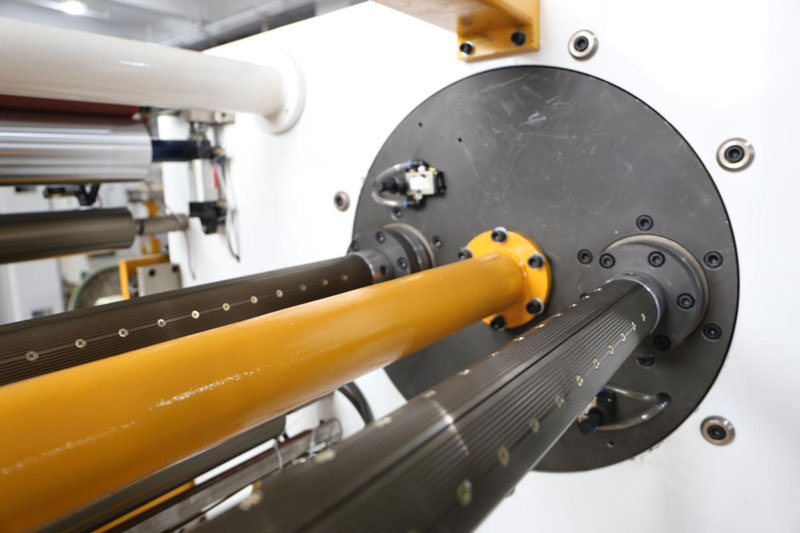

7: Friction shaft rewinding, piecewise tension control, which can adjust the degress of tightness automaticly, ensure perfect rewinding effect.

8: Full servo driven.

9: Dual turret rewinding, Maximize productivity

10: Auto laser core positioning, which can be synchronized with auto blade set to reduce tolerance and save operation time