|

|

|

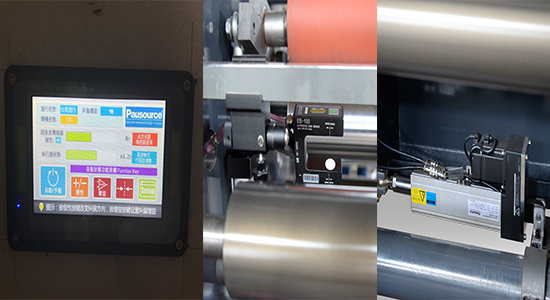

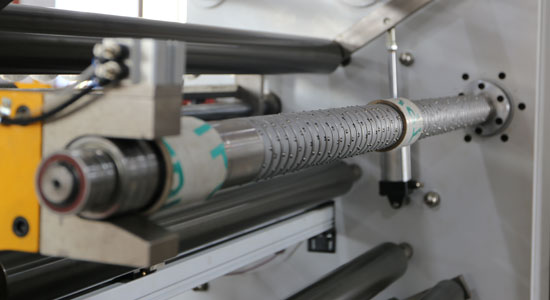

Model |

HCH2-650 |

|

Max. Unwinding width |

650mm |

|

Total power |

11kw |

|

Speed |

300~400m/min |

|

Precision |

±0.03mm |

|

Unwinding roller diameter |

∮1000mm |

|

Rewinding roller diameter |

∮600mm |

|

Machine weight |

1500kg |

we will contact you within 24 hours.