Features

Characteristic

1.SIEMENS PLC control, Touch screen on human machine interface with high resolution colors and easy operator controls.

2.Heavy machine body processed by CNC : ensure machine running in high speed stably and long time lifetime.

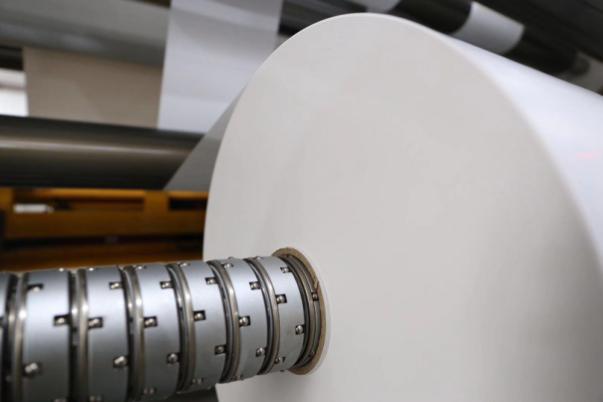

3.Shaft less heavy duty hydraulic loading.

4.Magnetic power brake and GERMANY FESTO Electronic proportional valve control the unwinding tension.

5.Dancer roller and traction section fine adjust, different type material adjustable can be done easily and conveniently.

6.Dancer roller adopted anti-wrinkling roller, avoid thin material wrinkling during unwinding and high speed running.

7.Main motor and rewinder motor adopted servo motor + INOVANCE inverter control.

8.Unwinding tension and rewinding tension controlled by SIMENS PLC and GERMANY FESTO proportional valves, automatic tension control, keep tension stable.

9.Web guide system adopted ultrasonic inspection, servo motor drive, ensure the material running stable and precision of align.

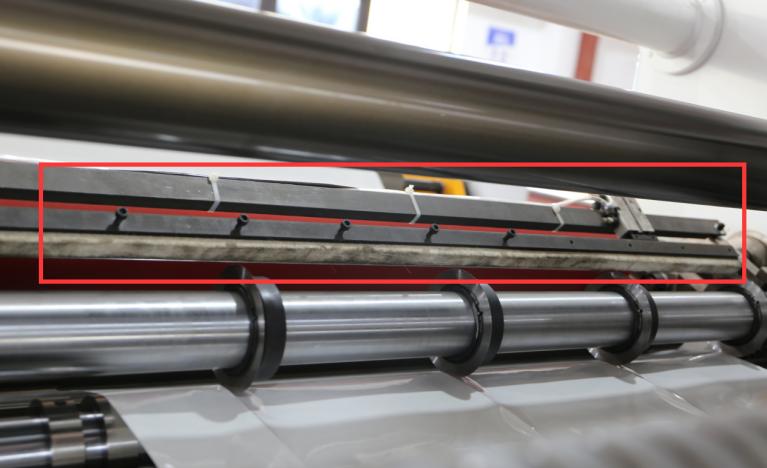

10.High quality KOREAN circular blade adopted, SKH-2 material ensure the lifetime.

11.Automatic counter wheel KOREA AUTONIC adopted, ensure higher precision for meter counting.

12.Synchronous belt transmission, low noise, running more steady.

13.Outside splicing table, which is more convenient for worker to operate and increase the productivity.

14.All the guide roll are processed by dynamic balance treatment, which make sure the machine can run in high speed stably.

15.Rubber roller adopted polyurethane material, more wear-resisting and own longer lifetime.

16.Aluminum roller adopted harden oxidation treatment, have the characteristic of high hardness and surface is more smooth, anti-scratch.

17.Friction shaft, each unit’s tension can be compensated automatically.

18.Double lay on roller make material rewinding more stable.

19.Material clamp roller adopted, when machine stop, it can hold the material, avoid it slip.Unloading frame reduce the unloading height, safe and convenient unloading.