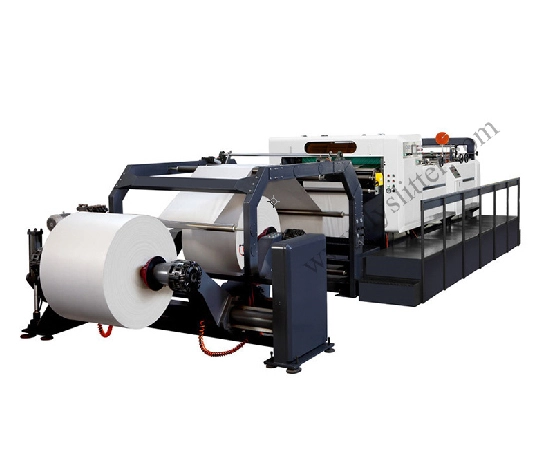

This series of servo-controlled paper sheeting machine is specialist for processing jumbo rolls of packing material into required size, such as carton, paper board,chrome paper,laser paper, kraft paper,printing paper, gold,silver,alu foil paper, laminated.

This series of servo-controlled semi paper cutting machine is specialist for processing jumbo rolls of packing material into required size, such as carton, paper board,chrome paper, laser paper, kraft paper,printing paper, gold, silver, alu foil paper, laminated paper, bond paper, matte couche, paper semi-gloss paper, thermal transfer paper, direct thermal paper, metallized paper, cardboard paper, thermal cardboard, etc. It is widely used in paper processing and printing packing.

MachineModel | LY-H1400 | LY-H1700 | LY-H1900 |

Reference weight of cutting paper | 50-500g/m2 | 50-500g/m2 | 50-500g/m2 |

Diameter of paper (Can be 1 roll,2roll,4 rolls loading ) | 1 roll1800mm | 1800mm | 1800mm |

2 roll 1800mm | 1800mm | 1800mm | |

4 rolls 1600mm | 1600mm | 1600mm | |

Width of paper | 1400mm | 1700mm | 1900mm |

Total power | 23KW | 25KW | 27KW |

Cutting length | 400-1600mm | 400-1600mm | 400-1600mm |

Cutting accuracy | +/-0.2mm | +/-0.2mm | +/-0.2mm |

Maximum cutting speed | 300cuts/min | 300cuts/min | 300cuts/min |

Maximum cutting meter speed | 300m/min | 300m/min | 300m/min |

Atmospheric pressure | 0.8MPa | 0.8MPa | 0.8MPa |

Power supply | AC380V/220Vx50HZ | AC380V/220Vx50HZ | AC380V/220Vx50HZ |

Total weight | 9000kg | 10000kg | 12000kg |

Dimensions | 9m×3.9m×2.35m | 9m×4.2m×2.35m | 9m×4.4m×2.35m |

Automatic roll unwinding unit is equipped with hydraulic shaftless roll stands two clamps and braking system, which are easy-to-use during roll manipulations;

Adopts FAG Original imported bearings;

Adopts JAPANESE CKD proportional valve;

This paper roll slitter rewinder adopts ITALY PHASE servo motor for controlling constant-length cutting;

It adopts GERMANY KEB servo drivers;

It adopts Simens PLC control, keeps the whole equipment's program and circuit control stable and runs without accident;

This automatic rotary type servo driven paper sheeting machine adopts 45 mm heavy-duty steel body to ensure smooth operation and long service life;

This 4 roll jumbo roll sheeter adopts Switzerland EHRE timing belt;

This roll paper slitter rewinder has the functions of high speed, can reach 300 cuts/min;

Conveyor belt adopts Holland Rapplon Belt;

Once the machine's program is set, the roll diameter does not need to be adjusted again, reducing manual effort.

Raloyal mission is :To creat and provide value to customers .

So as a enterprise with the strong sense of responsibility .

Raloyla can give the commiment to cusotmer :we provide not only 1 year gurantee ,but also lifelong service support .

The support included :Machine setup &trainning and the parts supply.

For the machine setup ,Customer have 2 ways to choose after receive the machine .

1: Raloyal provide the machine operation video ,drawing, manual etc to customer ,

Most customer have learned the operation well via these information.

2 : Raloyal arrange the service techincan to customer factory for machine set up and trainning .

No matter which way customer choose ,we can also creat a group (advised :wechat ),which will put service technican and the sales in ,in addition , the company CEO will also be there . which means when the operator have any doubt or question for the operation ,they can leave message to the group ,our service technician will reply it as soon as they saw it .

By the way ,we also upload the machine operation video in webiste ,the link path is :

https://www.lyslitter.com/engineering/slitter-machine-operation-video/

For the parts supply ,Raloyal promisie we will provide customer the machine parts (Raloyal machine ) for lifelong time ,which means any time you need part ,we are here .

and provide the part at cost price .

Raloyal ,your loyal partner.