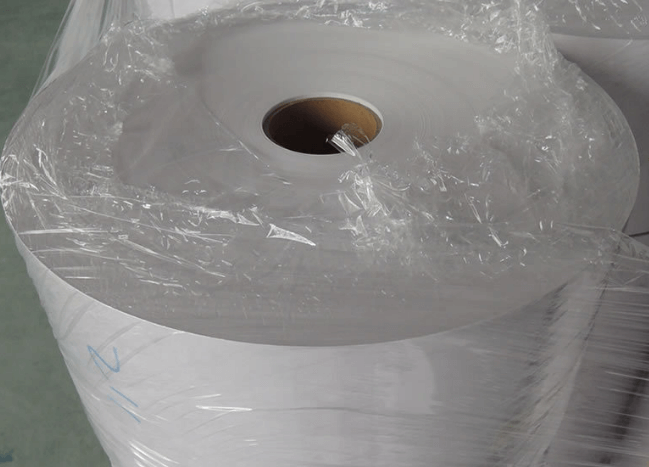

Label slitting machine is often suitable for slitting large mother wide rolls of stickers into narrower rolls of slitting machine. The self-adhesive slitting effect will affect the printing effect later. After slitting a volume of self-adhesive material, the following aspects of inspection should be done:

(1) Whether end surface of the self-adhesive rolls is neat or not. If the end surface of label rolls is not even, the paper will appear the "snake" phenomenon when unwinding the labels rolls, resulting in inaccurate overprinting. If the edge of the self-adhesive material rolls has clucking or cracks, the self-adhesive material will be easily broken when printing, resulting in waste.

(2) Whether the core part of the volume of label rolls is loosen or not. If the self-adhesive material roll is loose in the core part of the volume, it will result in inaccurate overprinting.

(3) whether the two ends of the self-adhesive material roll are loose and consistent together. It may be caused by different rewinding tension, or moisture deformation of one end of the self-adhesive material. If there is a web guide on the flexo printing machine, it can solve this issue.