Use the high speed slitting machine is applicable to PE, PP, PET, PVC, and other plastic films, paper, composite film, the aluminum film, color film. It is the ideal model of the film.

This machine is the best suit for high-quality demand and mass production. It is ideal for large diameter heavy rolls. Strong stability and long service life.

Bond paper, matte couche, paper semi-gloss paper, thermal transfer paper, direct thermal paper, metallized paper, cardboard paper, thermal cardboard, etc.

USE:

This series of slitting machines with an incredibly high speed in slitting is one of the flagship machines in our company. With the greatest equipment offered, this machine is supposed to do any kind of slitting stuff. So, as far as I’m concerned, it may be one of the ideal slitting machines in the world.

Thanks to its high configuration, we can use this series of machines to slit package of the high-quality products for some deluxe stores. Without any doubt, it performs extraordinarily on slitting works of plastic films, electronic films, paper, optical films, metal films, trademarks and adhesive tapes, etc. So, we have strong belief that it is a great choice for some slitting companies or factories to purchase.

Release Liners (Paper/ Film) and Label Stocks. Our range consists of Release Paper Liners, Release Film Liners, Self Adhesive Paper Label Stocks (Cromo Art, Maplitho, Mirror Coat, Flourocent paper,Thermal Transfer, Aluminium foil paper( golden and silverl ), pvc film label stocks, vinyl film label stocks, polyester film label stocks, Self Adhesive Film Label Stocks (Polyster Film (metalized/Clear), PVC Film(Color/ Transparent), Vinyls(Colour/Transparent) and Specialty Adhesive Tapes / Label stocks.

Characteristic:

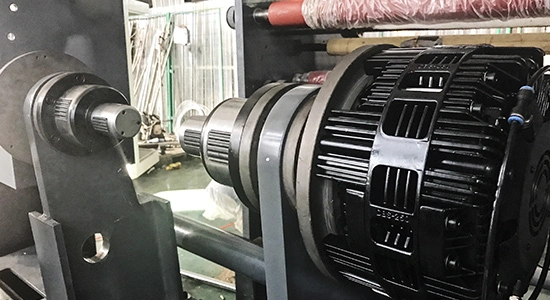

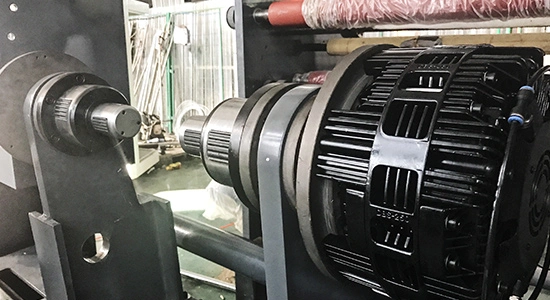

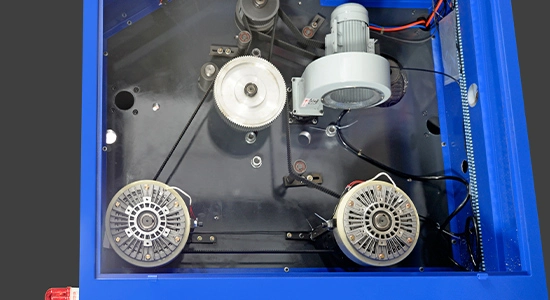

Compared to the last generation we designed, (which is this generation based on to design), this series of machines have been added another motor, to drive the rewind rolls for each. Therefore, one motor is used to control the unwinding part, while the other two motors are used to control the two slip shafts for each.

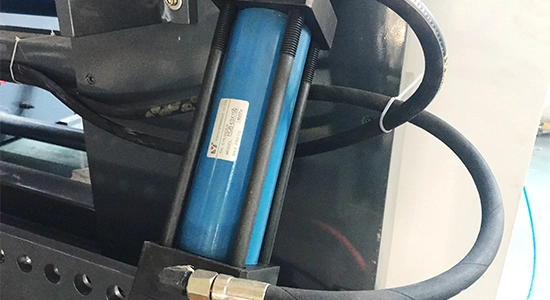

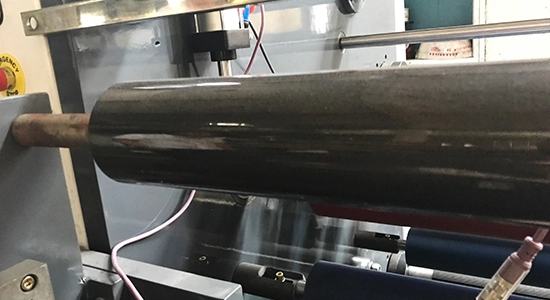

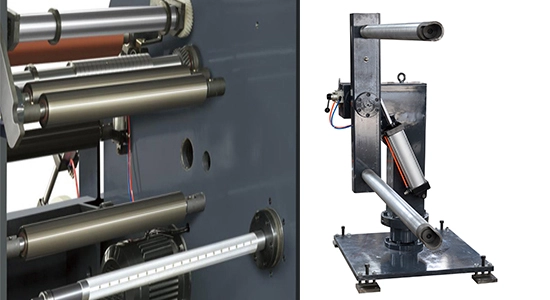

It is our flagship product, for now, numbered as ‘HCH3’, which means the 3rd generation. Besides, we have replaced the unwind part to pneumatic brake, realizing loading raw materials without shafts. What ‘smore, we have introduced and adopted the technology of shaftless loading through a hydraulic lift, which makes feeding automatically come true.

The flagship product is surely equipped with our highest-specification service of after sale. So, if you buy this type of machines, we are very honored to provide you any technology service, with the guarantee of a-year quality and longtime service and technical support. So, it is reachable that you will never be worried about any problems you might face because we will be with you forever.

Model | HCH3-1700 |

Max. Unwinding width | 1700mm |

Main motor power | 11kw |

Speed | 300~400m/min |

Precision | ±0.03mm |

Unwinding roller diameter | ∮1200mm |

Rewinding roller diameter | ∮2*800mm |

Machine weight | 10000kg |

Touch screen on Human machine interface (HMI)

Automatic loading system

Hydraulic lift up

Shaftless unwinding chuck

Pneumatic powder break

Pneumatic powder break

Ultrasonic rectification

Whole unwind stand can move horizontally, left and right.It can ensure the accuracy of slitting position.

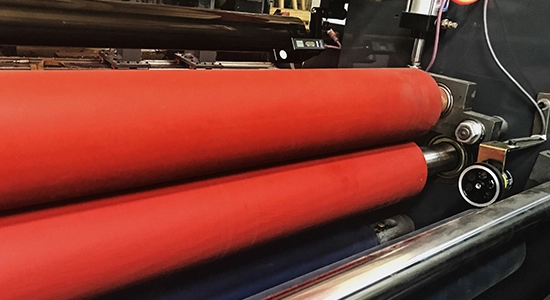

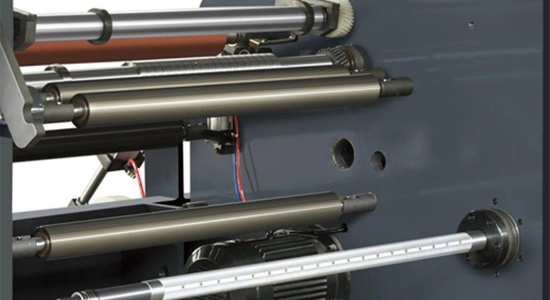

Polyurethane be uesd in rubber covered roller (wearproof)

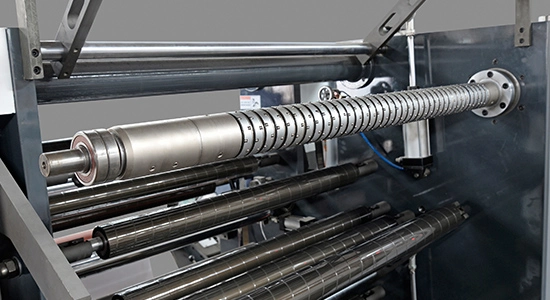

Aluminum rod after Hardness oxide (protection materials and scratch-proof)

The movement of rubber covered roller is controlled by the cylinder

Three Motors Winding: Servo motor

One motor drives upper rewind shaft, one drives lower rewind shaft and the third motor is connected to the main drive roller.

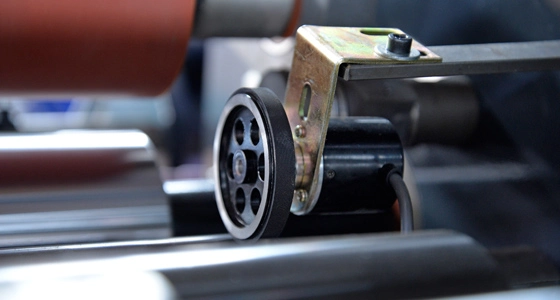

Synchronous belt

Shear cutter system (sharp, flexibleand slitting efficiently)

Automatic metering

Slip shaft

Dual rewind sations

Electronic proportional valve

PLC increase or decrease it according to the calculating difference automatically

Maintain the stable tension output during whole slitter rewinder operation.

Dual unload stations and automatic unloading

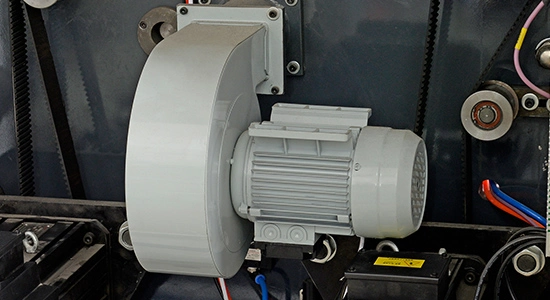

Equipped with blower and expulsion tube