The use of this flexo printing machine includes Roll, paper, non-woven, woven, PVC, OPP, BOPP, PE, NY, PET, CPP and other flexible packaging roll materials.

We are a professional manufacturer specializing in paper and label converting equipment, as well as printing machines.

We have established partnerships with global companies such as All4Label, Avery, and Arclad Group, along with Greece's largest food paper packaging company. In China, we collaborate with leading enterprises, including Guanhao—one of the country's largest paper product companies—and Fangda, the biggest paper company in China.

Our core business focuses on providing complete solutions for paper and label converting equipment and printing needs, tailored to meet our customers' requirements.

It is suitable for printing paper, thermal paper, paper board, paper cup, paper plate, paper bowl, wrapping paper, advertise paper, platter paper and etc., advertise paper; platter paper.

Flexo Printing Machine Application Industry:

On the basis of the end users/applications, major market share and growth for each application, including:

Food and Beverages

Pharmaceuticals

Personal Care

Industrial Labels

Retailers and Supermarkets

Logistics

Others

Our Difference

Machine model | LYT4-800 | LYT4-1000 | LYT4-1200 | LYT4-1300 |

Max. Printing material width | 800mm | 1000mm | 1200mm | 1300mm |

Max. Printing width | 760mm | 960mm | 1160mm | 1260mm |

Max. Unwinding diameter | 1300mm | |||

Max. Rewinding diameter | 1300mm | |||

Printing length range | 228-1000mm | |||

Printing speed | 5-100m∕min | |||

Register precision | ≤±0.15mm | |||

Printing color | As required | |||

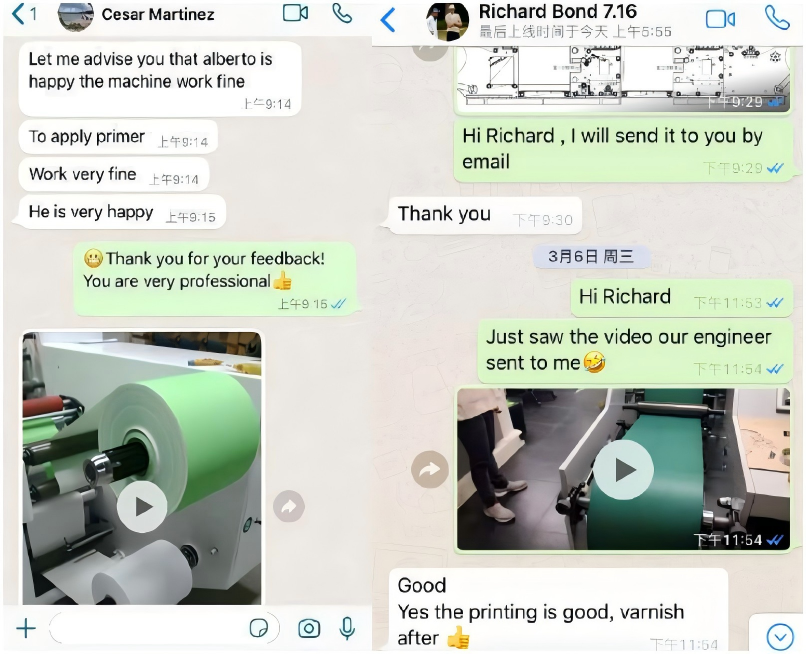

We are a professional manufacturer specializing in paper and label converting equipment, as well as printing machines.

We have established partnerships with global companies such as All4Label, Avery, and Arclad Group, along with Greece's largest food paper packaging company. In China, we collaborate with leading enterprises, including Guanhao—one of the country's largest paper product companies—and Fangda, the biggest paper company in China.

Our core business focuses on providing complete solutions for paper and label converting equipment and printing needs, tailored to meet our customers' requirements.