Application of HCH2-650 High Speed Slitting Machine

· Raw paper, release paper, paper board

· Adhesive paper

· Protective film

· PET, PVC, etc. film

· Release Liners (Paper/ Film) and Label Stocks

· Release Paper Liners

· Release Film Liners

· Self Adhesive Paper Label Stocks (Cromo Art, Maplitho, Mirror Coat, Flourocent paper,Thermal Transfer, Aluminium foil paper( golden and silverl )

· pvc film label stocks

· vinyl film label stocks

· polyester film label stocks

· Self Adhesive Film Label Stocks (Polyster Film (metalized/Clear)

· PVC Film(Color/ Transparent)

· Vinyls(Colour/Transparent) and Specialty Adhesive Tapes / Label stocks

Features of HCH2-650 High Speed Slitting Machine

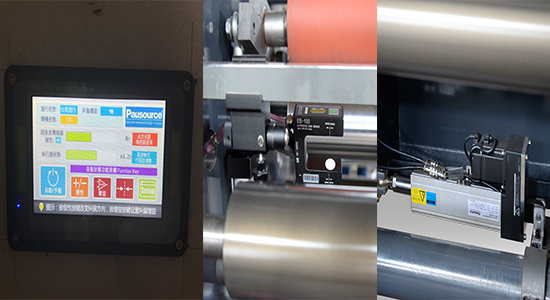

HCH2 series Self-adhesive Plain Labels slitter adopts a German Siemens control system with a high level of automatic.

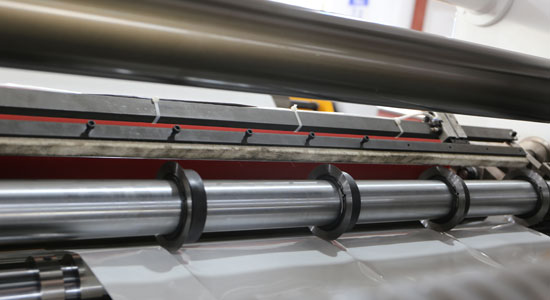

Double-bead friction shaft rewinding, sectional tension control, anti-scratch function.

2 servo motors control, high speed, and high quality.

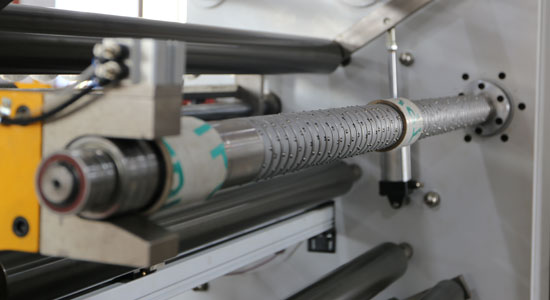

Option: shaft-less loading, semi-auto blades set