According to the latest research analysis, driven by the epidemic, global packaging production has developed faster than ever. However, the development of packaging production has caused many countries to pay more attention to environmental protection, and have successively introduced different plastic reduction measures to promote environmental protection concepts, and issued various "plastic bans," including China, Germany, South Australia, New York, USA, etc., 66% of consumers worldwide are willing to pay more for the products of companies that are committed to protecting the environment.

As the epidemic gradually eases, the industry has entered a new stage of resumption of industry and production. Production companies are actively waiting for production to relocate and rearrangement, trying to make a big splash in the market changed by the epidemic. Not to be outdone, the label industry is seeking breakthroughs, hoping to strengthen product flexibility and productivity, and quickly help companies seize opportunities to achieve transformation.

If you want to stand out in the label industry, you may consider the high speed slitting machine from RUIAN LOYAL MACHINERY CO., LTD.

HCH2-A High Speed Label Slitting Machine

Advantage:

Shaft less mechanical chuck and guide rail feeding system, outside designed splicing table for more friendly operating and increase productivity, full servo driven, option: finished product automatic pushing, 400m/min, semi-auto/full-auto blades set.

Technical parameter:

|

Machine model |

HCH2-1300A |

HCH2-1700A |

|

Material width |

1300mm |

1700mm |

|

Machine speed |

400m/min |

400m/min |

|

Slitting precision |

±0.03mm |

±0.03mm |

|

Unwinding diameter |

Φ1200mm |

Φ1200mm |

|

Rewinding diameter |

2*Φ600mm |

2*Φ600mm |

|

Main servo motor power |

4kw |

4kw |

|

Rewinding servo motor power |

11kw |

11kw |

|

Installation dimension |

2700*2650*1580mm |

2800*3150*1600mm |

|

Machine weight |

3500kg |

4000kg |

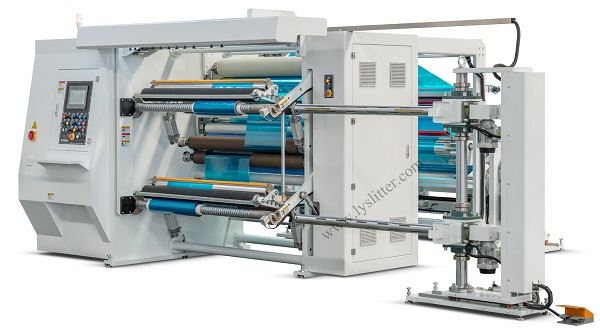

HCH3-B High speed slitting reiwnding machine

Difference:

Individual shaft-less loading, automatic unloading, overhead material path, double “S” structure, semi-auto blade set, 3 sets 11kw synchronous servo motors driven, etc.

Technical parameter:

|

Machine model |

HCH3-1300B |

HCH3-1700B |

HCH3-2000B |

|

Unwinding width |

1300mm |

1700mm |

2000mm |

|

Machine speed |

300m/min |

300m/min |

300m/min |

|

Slitting precision |

±0.03mm |

±0.03mm |

±0.03mm |

|

Unwinding diameter |

Φ1200mm |

Φ1200mm |

Φ1200mm |

|

Rewinding diameter |

2*Φ600mm |

2*Φ600mm |

2*Φ600mm |

|

Main motor power |

7.5kw |

11kw |

11kw |

|

Rewinding motor power |

2*7.5kw |

2*11kw |

2*11kw |

|

Installation dimension |

3980*4600*2250mm |

3980*5000*2250mm |

3980*5300*2250mm |

|

Machine weight |

6000kg |

7000kg |

9000kg |

LYS328 High speed self adhesive paper slitting machine

Main characteristics:

1. Ergonomic design, high precision automatic equipment processing, professional team assembly.

2. Unwidning shaftless clamping, swing loading and unloading.

3. Tension closed-loop control, PLC real-time monitoring.

4. The upper feeding structure can prevent secondary pollution and eliminate static electricity in the whole process.

5. Reserved installation position of contact type dust collector after slitting.

Technical parameter:

|

Machine model |

LYS328-1300 |

LYS328-1600 |

|

Unwinding width |

1300mm |

1600mm |

|

Machine speed |

500m/min |

500m/min |

|

Unwinding diameter |

Φ800mm |

Φ800mm |

|

Rewinding diameter |

2*Φ800mm |

2*Φ800mm |